Heavy industry

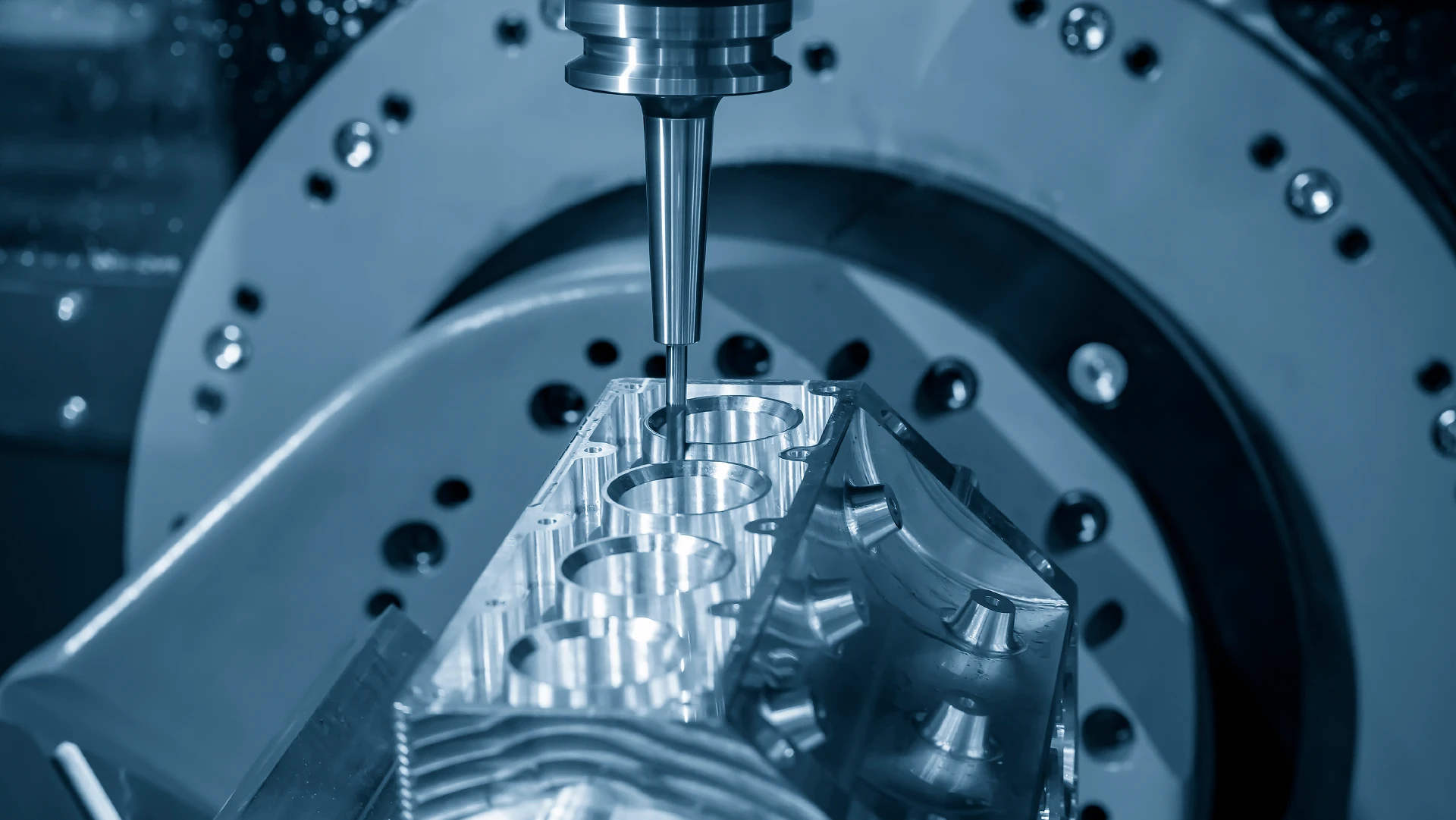

Heavy industry deploys automated, high-tech equipment to affect efficient and precise production.

Protecting valuable assets and preventing unplanned downtime is critical to these processes. Get constant oversight and early warning of machine failures—let AiSight handle the weight.

Value and benefits

Efficient use of materials

From the subtractive process of machining, to the additive process of coating, machine faults lead to substandard production and wasted materials.

Asset care optimization

Cutting parts wear out and break. Plan necessary repairs ahead and keep machines operating at their best.

Reduced production slowdowns

Delays for unplanned maintenance are delays to production. Keep every part of every machine healthy, and production can continue.