FMCGs

Production in the fast moving consumer goods (FMCG) industry moves at one speed:

fast. Avoid interruptions for unplanned machine maintenance; keep products moving out the door and onto shelves fast. Take the lead—with AiSight.

Value and benefits

Products on the shelf

FMCGs are high-turnover products—they fly off the shelf as fast as they arrive. Keeping production running means you keep shelves stocked with your products, not your competitor’s.

Hygiene

Edible goods are perishable and need to be sanitary. Avoiding breakdowns means avoiding spoiling and sanitation issues which could ruin a batch or worse, trigger recalls or plant shutdowns.

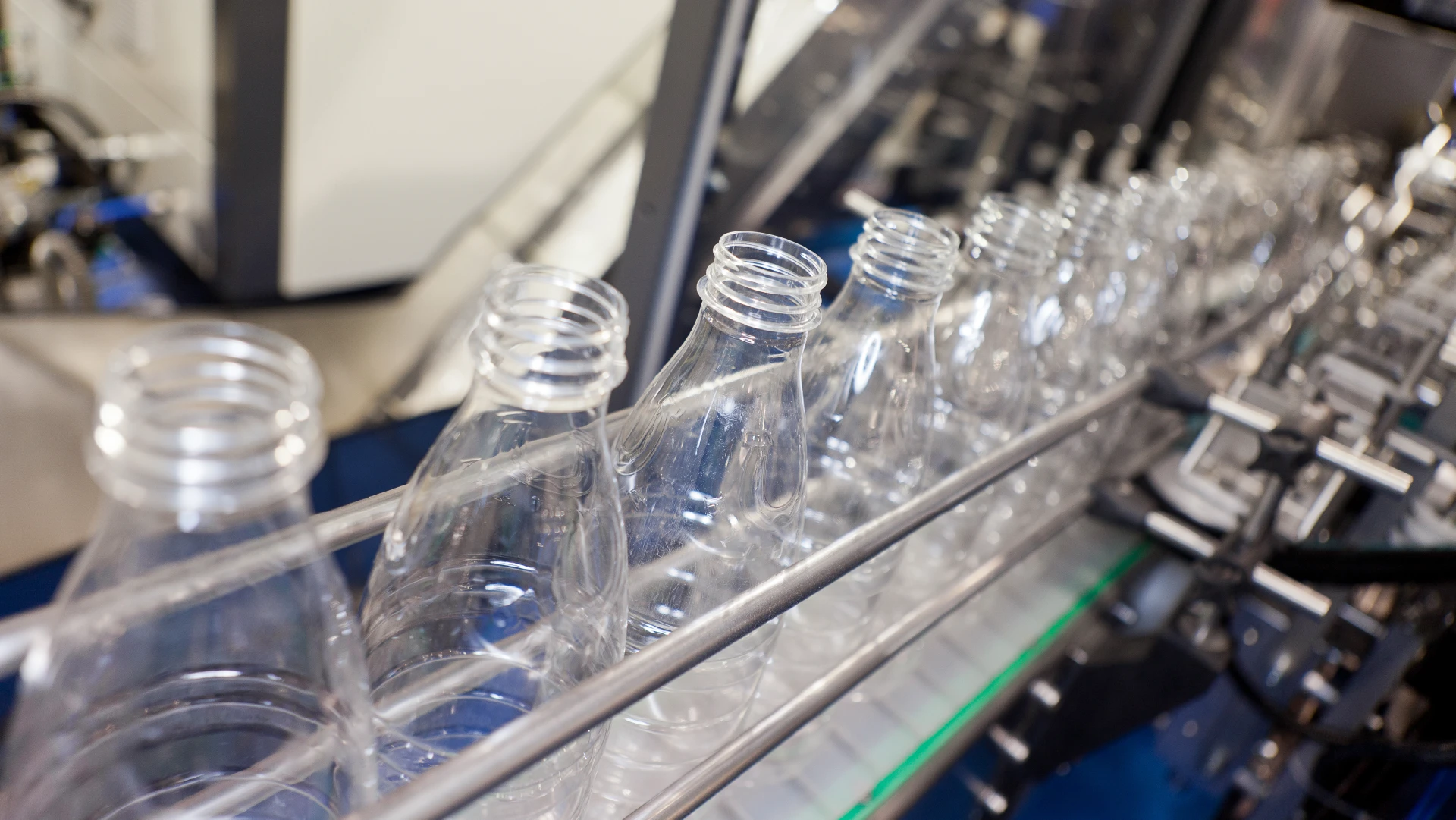

Prevent bottle jams

Bottling thousands of beverages an hour is an act of precision. Keep this delicate process in motion to avoid the jams that can reduce production to zero bottles, each and every hour.

Asset care optimization

Optimally, your equipment should produce as much as possible for as long as possible. Predictive maintenance allows you to maximize efficiency while allowing for the maintenance necessary to keep your machines running.