Want to try Nubo Sphere?

Get in contact with us. We are happy to demonstrate what our solution can do for you!

Next-generation CH4 sensing technology by Sensirion: reliable and cost-efficient

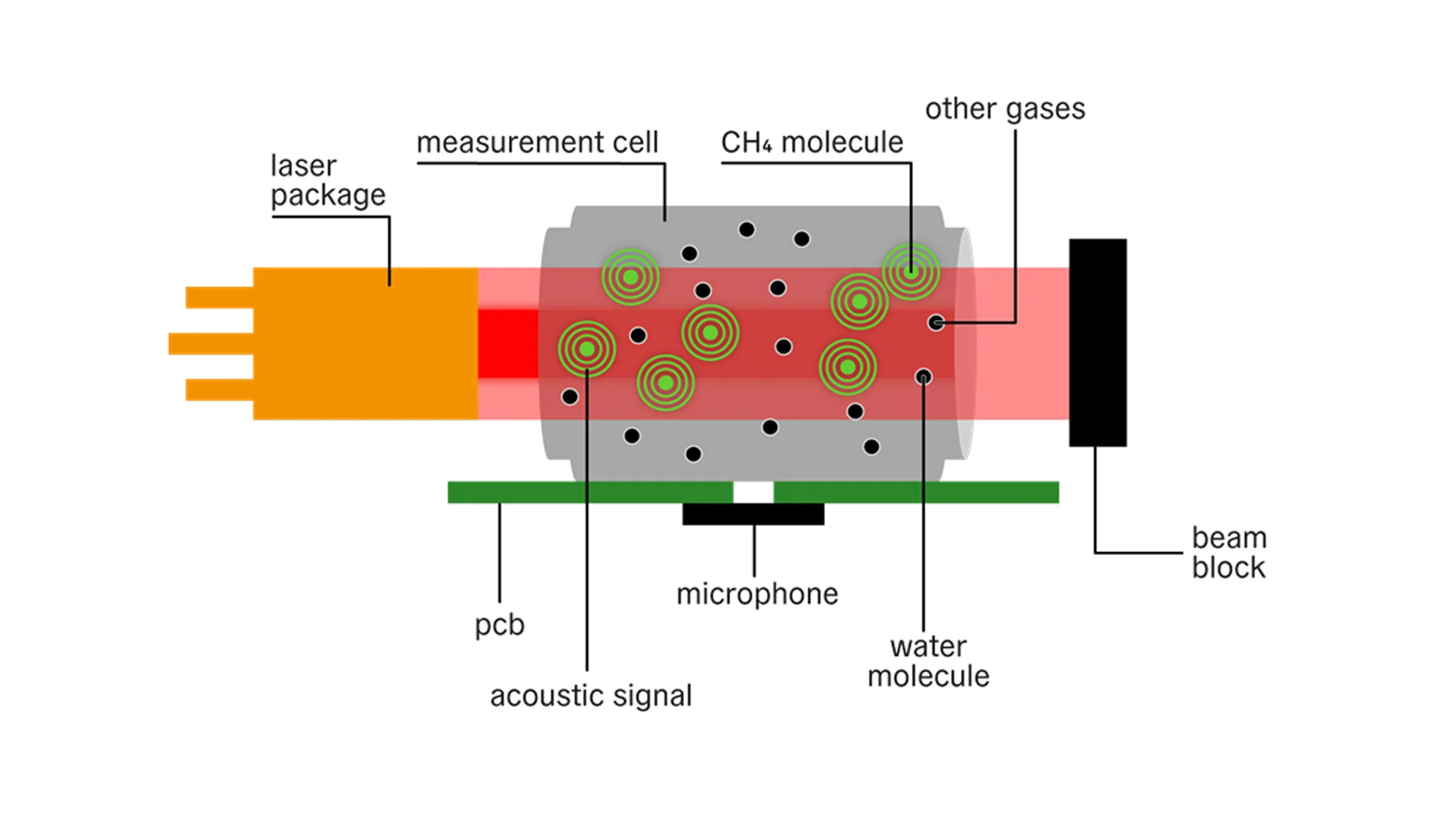

Photoacoustics allows the miniaturization of a well-established and reliable measurement principle like laser spectroscopy to not only increase energy efficiency but more importantly it reduces costs and hits the sweet spot in performance versus price. This groundbreaking innovation is the result of Sensirion's 25+ years of experience in developing scalable sensor technology, and is specifically designed to meet the requirements of the oil and gas industry in its efforts to monitor and reduce methane emissions. The combination of the following specifications allows across-the-board improvement in detection, localization and quantification accuracy, especially over metal-oxide based monitoring solutions. This was showcased during the blind, controlled release ADED 2023 test campaign at the METEC facility operated by Colorado State University.

In this blog article we showcase how quality insights on methane leaks are based on quality methane measurements. That's the reason why Nubo Sphere uses proprietary sensor technology designed specifically for emissions monitoring on oil and gas sites.

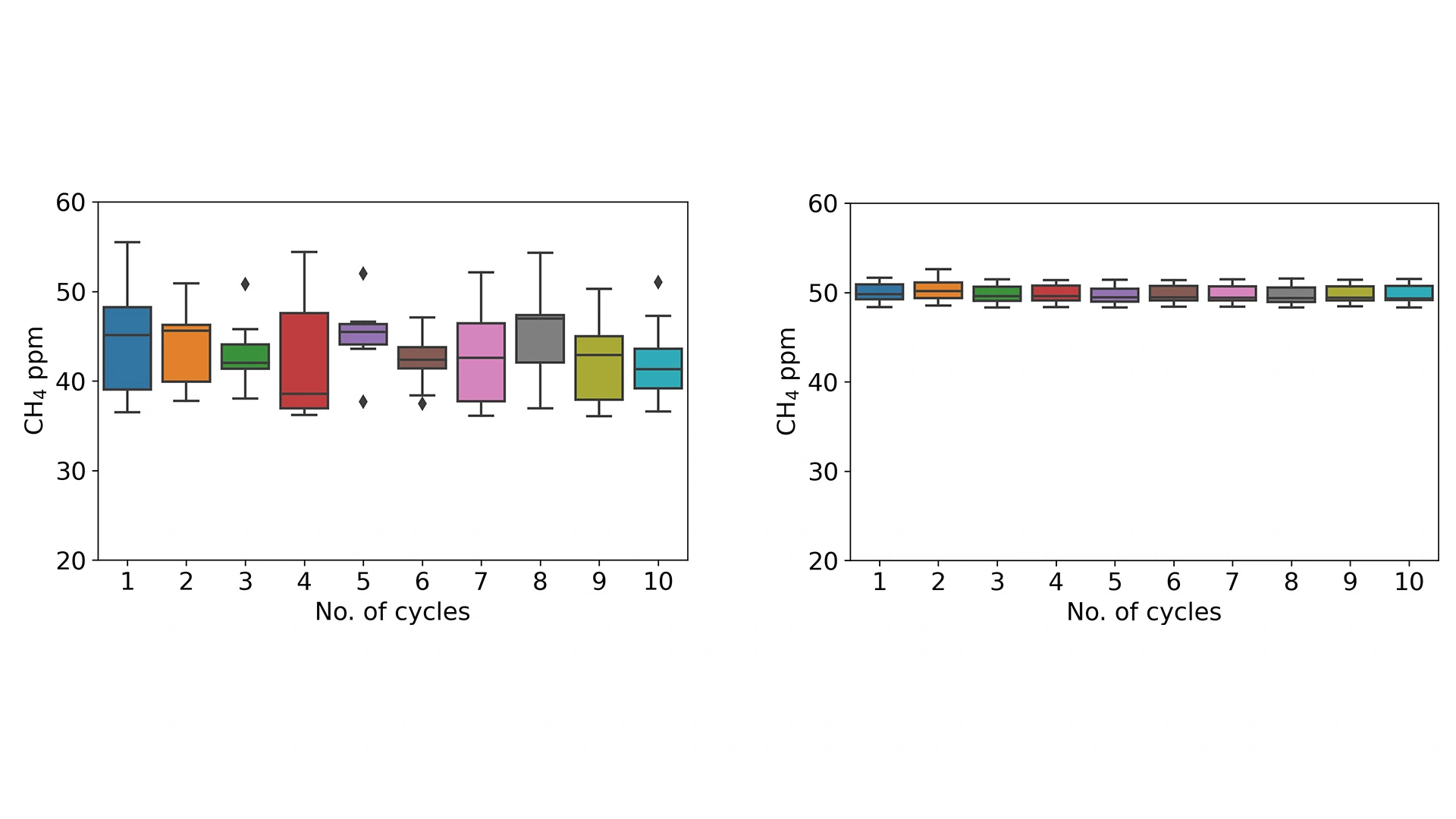

The ability to accurately determine absolute concentration measurements of methane in ambient air, above background levels, at any time and under many environmental conditions, is key when estimating the locations and rates of emission sources. Sensirion Connected Solutions’ sensor design has improved accuracy, repeatability and device-to-device variation by several factors each compared to metal-oxide sensors. This is crucial to avoid over- or underreporting, false positives and to enable reliable site-level emissions quantification for years of operation. On the image you can see a laboratory test setup: 10 cycles of 50 ppm methane in a gas monitoring system (GMS). Each cycle represents measurements from 6 devices for both MOx (left) and Sensirion’s proprietary photoacoustics-based sensor technology (right). Improved absolute accuracy, high repeatability and low device-to-device variation is shown.

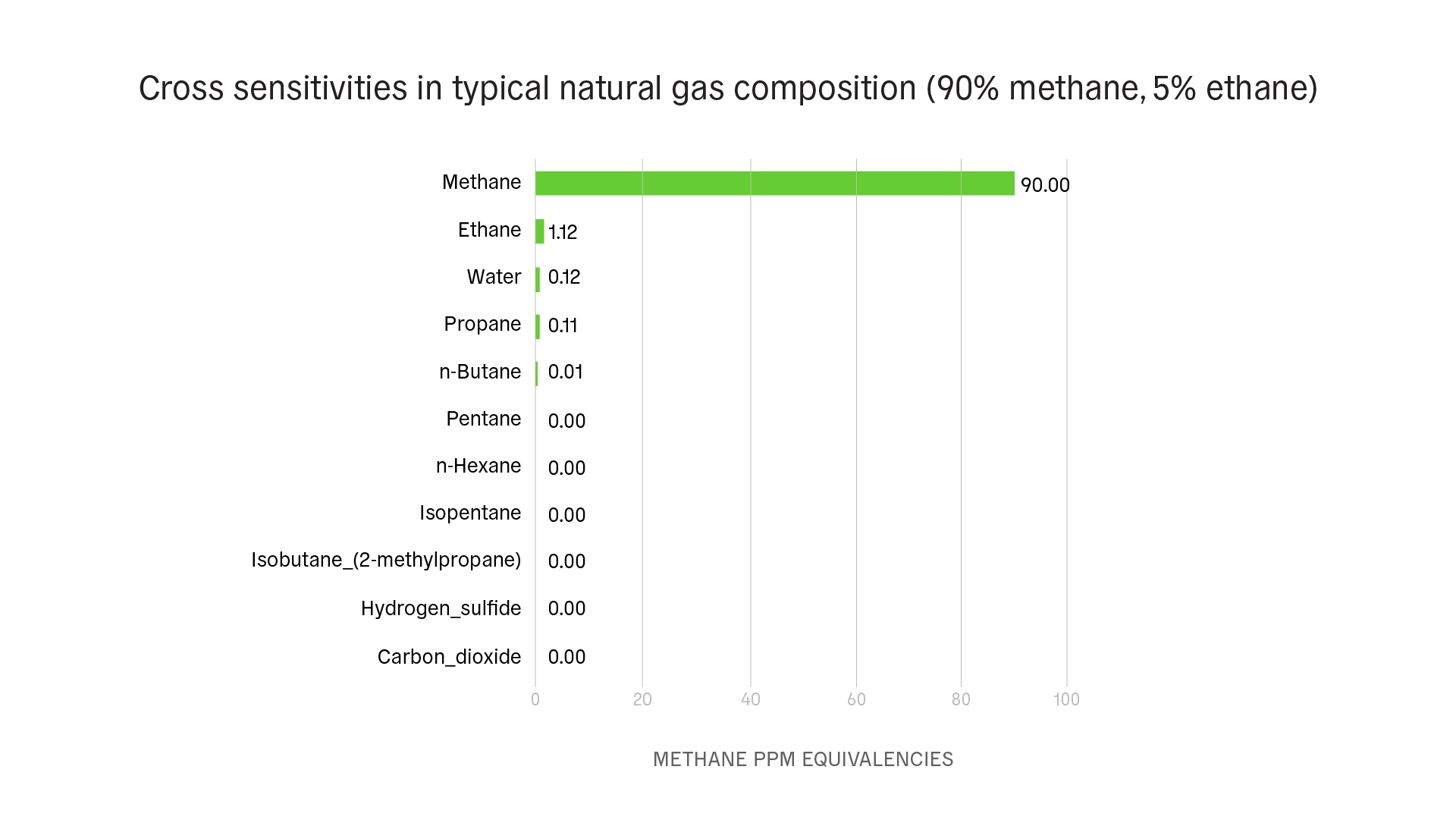

Our photoacoustic-based laser spectroscopy sensor technology offers highest specificity for methane in continuous monitoring solutions, eliminating false positives and enabling accurate methane emissions measurements. In contrast, traditional metal oxide gas sensors are sensitive to hydrogen (H2), which is present in oil and gas facilities. They are also highly sensitive to ambient humidity and temperature. Consequently, one of the development goals for our proprietary, cost-efficient methane sensor technology was to overcome cross-sensitivities to the maximum extent, especially with regard to the gases present at oil and gas sites, which is key to achieving much more reliable and long-term stable performance in the field. By relying on Sensirion's extensive expertise in developing state-of-the-art sensors, we were able to achieve a high methane specificity of 99% in a miniaturized sensor package to keep costs low, as required by the oil and gas industry. Our photoacoustic-based laser spectroscopy sensor technology exploits the distinct light absorption patterns of methane molecules in the mid-infrared absorption bands, resulting in minimal cross sensitivity to other gases of 1%. The graph shows the sensor measurement contributions of the gases present in a typical natural gas mixture. Assuming a natural gas mixture of 90% methane and 5% ethane, this gives a sensor output of ~91 ppm, of which 90 ppm is actually methane and only 1 ppm is due to ethane absorption.

Thanks to the true one-second response time of Sensirion Connected Solutions’ laser spectroscopy sensor technology—impossible with MOx sensors—the movement of methane plumes resolve on a microscale. A higher resolution provides a better representation of reality and, consequently, improves localization accuracy.

By relying on Sensirion’s extensive know-how in developing reliable and scalable sensor technology, this next-generation methane sensor offers long-term, stable measurements across a wide range of environmental conditions. These laser spectroscopy sensors require no in-field re-calibration and, as part of a cartridge-based sensor system, are easy to upgrade or exchange. Their lifetime of six years has been demonstrated through accelerated aging tests. This supports the low total cost of ownership of the Nubo Sphere solution.

Get in contact with us. We are happy to demonstrate what our solution can do for you!

Get in contact with us. We are happy to demonstrate what our solution can do for you!